玻璃磨边机的主要种类及特点

发布时间:

2023-02-07

要选择磨边机,首先得对磨边机的种类及特点有所了解。因磨边机的机器型号目前国内没有统一的编排规范,所以本文不再列举机械型号。

1、单臂异形磨边机(简称异形机或单臂机)

异形机的最大特点是用途广泛,价格低廉。

异形机既可以磨直边,也可磨圆边、鸭嘴边,还可磨斜边;既可以磨圆形工件,也可磨椭圆及异形工件。在独立吸盘上装上靠模,用异形机可以磨一些形状不规则的工件。

异形机结构简单,制造成本相对较低,所以价格也比较便宜,一般的国产机两万元左右就能买到。

2、直线磨边机

直线磨边机的特点有三:一是用途比较单一,只能磨各类直线边;二是可连续性磨削,生产效率较高;三是可磨削尺寸较大的平板玻璃。

直线磨边机是各类磨边机中品种、规格最多的磨边机,按能磨削的直线边的不同,它又可分为如下三种:

(1)直线磨边机(简称直边机)

直边机只能磨削玻璃的平底边及两棱角,按磨头数分,有三、五、八、九、十、十三、十四磨头等数种机型。一般来说,磨头数越多,则磨削精度和生产效率越高,相应地机器的价格也越高。而电脑控制的直边机(一般磨头数都在十或十以上)则价格更高。

近些年来,国内市场上又出现一种既可磨平底边,又可磨45°底边的两用直边机,用量也比较多。另外还有可磨一组或两组互成角度底边的磨边机,叫多级磨边机。这种机型磨头较多,一般为电脑控制,设备价格相对较高。

(2)直线圆(简称圆边机)

圆边机可以磨削玻璃的圆边、鸭嘴边等,在家具、玻璃的加工中用的较多。

圆边机也有三、五、六、七、八、九磨头等数种机型。

(3)直线斜边机(简称斜边机)

斜边机一般用于磨削玻璃3~20o的斜边。现在,有的斜边机也可磨削45°的斜边。

斜边机按磨头数分,也有七、八、九、十、十一、十四磨头等机型。

近些年来又出现一种能在玻璃斜边上磨出各种波浪花纹的斜边机,叫波浪斜边机。

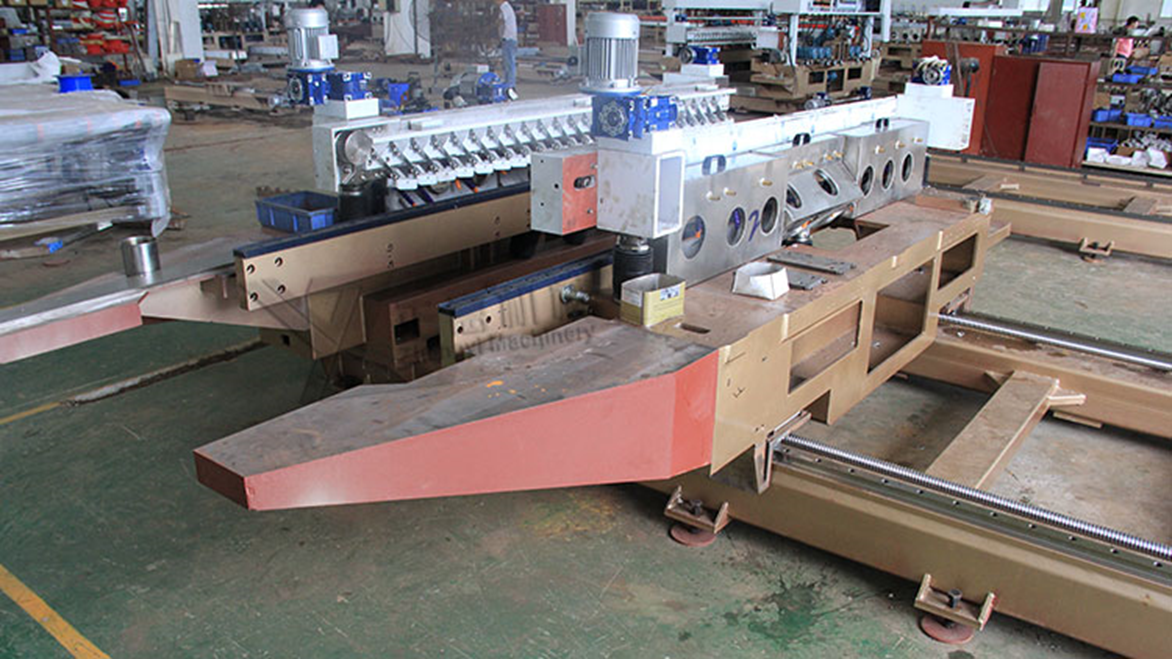

(4)直线双边磨边机(简称双边磨机)

双边磨机的特点是可同时磨削玻璃的两条对边,加工精度好,生产效率高,适用于大批量的玻璃磨边生产。

双边磨机按使用性能分有双直边磨边机和双圆边磨边机两种,其中双直边磨边机用的较多。

双边磨机按磨削玻璃宽度的不同可分为中小型和大型两种。最大磨削宽度在两米以下的称为中、小型双边磨机,磨头配置有四、六、八、十二磨头等。最大磨削宽度在两米及两米以上的称为大型双边磨机,磨头配置有十六、二十、二十二磨头等。大型双边磨机一般为电脑控制,自动化程度较高,适于磨削大尺寸平板玻璃,但是,这种设备的价格比较昂贵。

3、内圆磨边机(简称内圆机)

内圆机的特点是结构简单,价格低廉,但用途比较单一,主要适于加工圆周边(可以是正圆,也可是椭圆或异形圆)。

现国内有些厂生产的内圆机,摆臂较长,使磨头的摆动范围加大。这种机型不但可磨内圆,也可兼磨外圆,又称为内外圆磨边机。

4、其他磨边机及专用磨边机

除以上介绍的磨边机以外,还有一些结构简单、用途单一的磨边机,如倒角机、小圆片机、抛光机等。另外还有一些专门加工某种产品的专用磨边机,如汽车后视镜磨边机、洗手盆磨边机等。

5、进口磨边机

进口机质量好、精度高,生产效率和使用寿命都要比国内机高很多。但进口机价格昂贵,一般为国内同类机价格的3~10倍。

进口磨边机来自意大利生产的较多,质量也较好。另外还有来自韩国、台湾等地的磨边机用的也较多。

6、靠模磨边机(简称靠模机仿形机)

靠模机利用模板准确定位,可精确磨削圆形或异形玻璃的直边、圆边、鸭嘴边、斜边等,这种磨边机磨出的玻璃形状准确,尺寸统一,生产效率较高。

使用靠模磨边机需要制作专门的模板,当生产品种较多时,不但制作模板费用较高,而且管理、更换模板也较麻烦,因此这种机型适用于生产品种不多,但生产批量很大的玻璃加工。

靠模机也有单头、双头、四头、六头等数种机型,其中四头及六头靠模机可一次磨削现国内磨边机生产厂家有近百家之多,而其中生产规模较大、产品质量稳定、售后服务体系完善、信誉度较高的生产厂家只有10多家,我们购买时首先要选择这些厂家生产的磨边机,因这些厂家生产的磨边机虽在价格上比小厂生产的要高一些,但质量和售后服务要比小厂好得多,用起来比较放心。即使在使用中出现一些技术问题,这些厂家也会帮你及时解决的。一般在保修期内都是免费的,过保修期适当收取成本费用。如果对已购买的机器设备不满意,还可以退货或更换。

另外要特别说明的是,如果需购买的磨边机种类和数量较多,最好是选用同一个厂家生产的。因为这样做对日后的生产、管理、维修等要方便许多,并且由于是批量购买,在价格和服务上还能得到更多的优惠,笔者对许多玻璃制品厂了解发现,不少厂家使用的生产设备都产自少数几个设备制造厂。

如果玻璃产品磨削精度的要求不太高,可考虑购买一些小厂生产的磨边机。这样可以节省购买设备的投资,因小厂的机器价格相对较便宜,一般能比大厂生产的低10%~20%。

如果玻璃产品加工的规模较大,资金比较充足,而且对玻璃产品精度要求高,生产批量大,则可以考虑购买几台进口磨边机。进口机虽价格昂贵,但它加工精度高,故障率低,关键时刻能发挥优势。有些厂家的进口磨边机用了十多年仍在使用,且加工精度仍比国内机高。所以从某种意义上来说买进口机也是相当划算的。

Glass edge grinding machine's main types and characteristics

Glass edge grinding machine's main types and characteristics

Want to choose edge grinding machine, first to edge grinding machine understanding the type and characteristics. For doubleedge grinding machine machine model at present domestic no unified layout norms, so this paper no longer lists mechanical model.

1, single-arm abnormity doubleedge grinding machine (hereinafter referred to as abnormity machine or single arm machine)

The biggest characteristic of special-shaped machine is used widely, the price is cheap.

Abnormity machine can grind straight edge, also can ground round edge, duck lips, still can grind tapered side plain wheels; Can grind workpiece, also can whet circular ellipse and abnormity workpiece. In independent chuck modeling, filled with special-shaped machine can grind some irregularly shaped workpieces.

Abnormity machine simple in structure, manufacture relatively low cost, so the price is cheaper also, general GuoChanJi two thousand yuan can be bought.

2, linear edge grinding machine

The characteristics of linear edge grinding machine has 3: it is to use more onefold, grinding various linear edge; only 2 it is grinding, the production efficiency can be continuity higher; Three is bigger flat glass grinding size.

Linear edge grinding machine is all kinds of edge grinding machine kinds and sizes most doubleedge grinding machine, according to the edge of the straight line can grinding different, it can divide again as follows three:

(1) linear edge grinding machine (hereinafter referred to as straight edge machine)

Straight edge machine can only grinding glass edges and flat, according to two edges, there are three grinding head count points, five, eight, nine, ten, 13, 14 ground top several models. Generally speaking, grinding head count is more, grinding accuracy and efficiency of the machine is taller, accordingly the higher price. And computer control straight edge machine (general mill in ten or are broken down by more than ten) is the price higher.

In recent years, domestic market appeared again a kind already may be grinding pan edge, and may be grinding 45 ° hemline amphibious straight edge machine, dosage is more also. Another can whet a group or two groups to each Angle hemline is edging machine, called multi-stage edge grinding machine. This machine for grinding head more, general computer control, equipment value is relative taller.

(2) linear circular (hereinafter referred to as round margin machines)

Round the edge roller can grinding glass edge, duck lips round in furniture, glass processing with more.

Circular edge machine also has three, five, six, seven, eight, nine ground top several models.

(3) linear beveling machine (abbreviation beveling machine)

Beveling machine for grinding commonly 3 ~ 20o of the hypotenuse of glass. Now, some beveling machine can also be grinding 45 ° of the hypotenuse of.

Beveling machine press grinding head count points, also has seven, eight, nine, ten, eleven, fourteen grinding top models.

In recent years and appears on a glass on the hypotenuse of wave patterns of grinding, beveling machine called wave beveling machine.

(4) linear bilateral doubleedge grinding machine (hereinafter referred to as bilateral mill)

The characteristics of bilateral grinding machine is also the two edge grinding glass, processing precision, high production efficiency, suitable for large quantities of glass edging production.

Bilateral mill by use performance points have double straight edge doubleedge grinding machine and double circular edge doubleedge grinding machine two kinds, including double straight edge doubleedge grinding machine with more.

Bilateral mill press grinding glass width can be divided into two kinds of medium and large. Biggest in two meters below the grinding width called medium and small bilateral grinding machine, grinding head configuration has four, six, eight, and twelve ground top. Biggest in two meters and grinding width two meters above called large bilateral mill, grinding head configuration has 16, 20, 22 ground top. Large bilateral mill is commonly computer control, automation degree is higher, suitable for grinding large size plate glass, however, this equipment are expensive.

Three, inner circle edge grinding machine (abbreviation is semi-atuo machine)

The characteristics of semi-atuo machine is simple in structure, low prices, but it is a single, mainly is suitable for machining circle surrounding (may be positive, but oval or round profiled circle).

Now the domestic some factory in circular machine, swinging arm longer, make grinding head swinging increased range. This model not only can whet, also can hold concurrently semi-atuo external circular grinding, also known as inside and outside round edge grinding machine.

4, other edge grinding machine and special edge grinding machine

In addition to the above the edge grinding machine is introduced, besides some simple structure, USES a single edge grinding machine, such as chamfering machine, small round slice machine, polishing machine, etc. There is also some special processing some product special edge grinding machine, such as auto rearview mirror edge grinding machine, lavabo doubleedge grinding machine, etc.

5, import edge grinding machine

JinKouJi high precision, good quality, efficiency and service life is much higher than domestic machine. But JinKouJi expensive, generally for domestic similar machine price 3 ~ 10 times.

Import doubleedge grinding machine from Italy production more, quality is better also. Another comes from South Korea and Taiwan with the edge grinding machine and more.

6, modeling edge grinding machine (abbreviation modeling machine imitation shape machine)

Modeling machine using the template accurate positioning, can accuracy grinding round or shaped glass straight edge, round the edges, duck lips, beveling etc, this edge grinding machine grinded glass shape accurate, high efficiency unification, the production size.

Use modeling doubleedge grinding machine needs to prepare special template, when production of a long, not only higher cost of making stencil and management, replacing template also a trouble, so the machines are suitable for production of small, but production batch big glass processing.

Modeling machine is also a single head, double head, four, six top several models, including four and six modeling machine can be a grinding now domestic doubleedge grinding machine manufacturers have nearly hundred, but which produce larger scale, stable product quality and after-sales service system, credibility higher manufacturers only more than 10 factories, we should first choice when buying these manufacturers doubleedge grinding machine, for these factories though edging machines in price than small factory is higher, but the quality and after-sales service to much better than the small factory, more comfortable with it. Even in use appear some technical problems, these manufacturers will also help you out in time. General under warranty are free, charge cost warranty appropriate. If already purchase of machinery and equipment are not satisfied, can also return or replacement.

In addition to special explanation is, if you want to buy doubleedge grinding machine type and quantity is more, had better be to choose the same manufacturers. Because doing so in the future production, management, maintenance, and convenient because many are batch purchase in price and service, also can get more favorable, the author for many glass products factory understand found, many manufacturers use production equipment are produced in a handful of equipment factory.

If the glass products grinding accuracy requirement is not too high, can consider to buy a small factory edge grinding machine. This saves purchased equipment investment, because of the small factory price relatively cheap, machine than giant general can production low 10% ~ 20%.

If the glass products processing, the larger scale, and more sufficient funds to glass products, production batch of high accuracy requirement, can consider buying a big several imported edge grinding machine. JinKouJi though expensive, but it high machining accuracy, low failure rate, the key moments to play advantage. Some manufacturers of imported doubleedge grinding machine used ten years still in use, and the processing precision is still better than domestic machine high. So in a sense to buy JinKouJi is quite cost-effective.

相关新闻